Printing and packaging. Mobile computer digital, plastic, glass, electronics, automobile, medical, metal and other industries.

Basic parameters

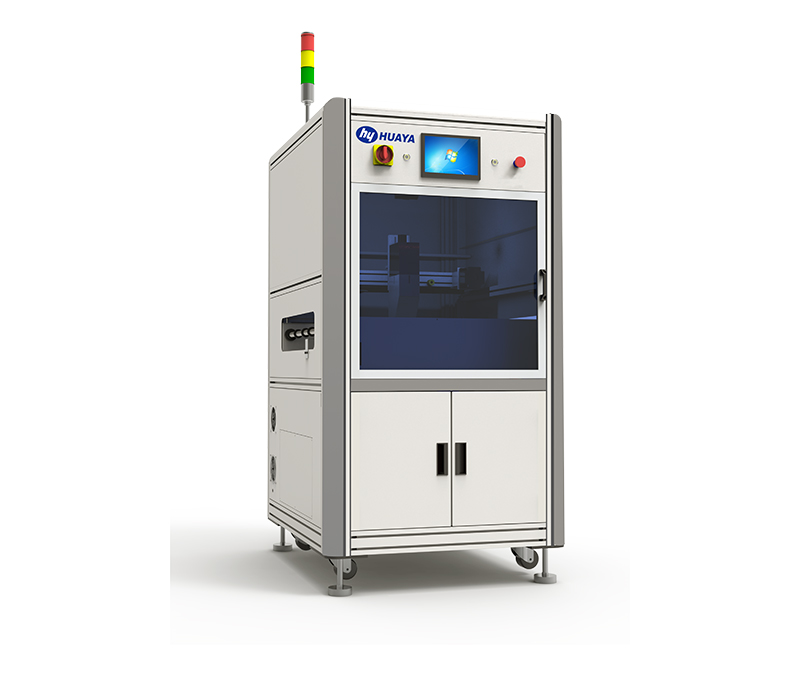

Model: Hysp-2

Size: L880*W1060*H1670 (mm)

Advantage

• PLC+touch screen, fault sound light alarm and menu display;

• Use step motor+synchronous drive;

• Equipped with-rotating head or pointed spray gun;

• The online rail transmission system can connect to the front and rear equipment communication;

• Can be programmed online;

Function

• activation: greatly improve the wetting performance of the surface and form the surface of activity;

• Cleaning: Remove dust and oil, fine cleaning and removing electrostatic;

• Coating: Provide functional surfaces through surface coating;

• Improve the ability to attach to the surface;

• Improve the reliability and durability of surface adhesion;

Equipment parameters

| Functional configuration | technical parameter | Functional configuration | technical parameter |

| weight | 300kg | valid itinerary | x=400mm Y=450mm |

| control | PLC+touch screen | processing power | 1000w |

| programmatically | Manual programming | single processing width | Rotary head 50mm / pointed head 8-10mm |

| conveyor track | rolling conveying | Efficient handling height | 3~15mm |

| conveying height | 900±20mm | processing speed | Maximum: 300mm/S |

| Stepper motor conveying | 20m/min | flame length | 20mm |

| x·Y drive method | Stepper motor + timing belt | Input air pressure alarm | Menu + sound and light alarm |

| maximum movement speed | 300mm/S | Input voltage | 220V 50~60HZ |

| Running accuracy | ±04mm | barometric pressure | 4kg/cm2 |

| Number of guns | 1 set | Air supply type | Compressed air or nitrogen |

| Gun Type | Rotary head (standard) pointed | total power | 2kw |

| working direction | Left to right (standard) right to left | safety standard | CE |

| Repeatability | ±0.4mm |